Our Work

Teamwork Creates Streamlined Efficiency for Distribution of Medication

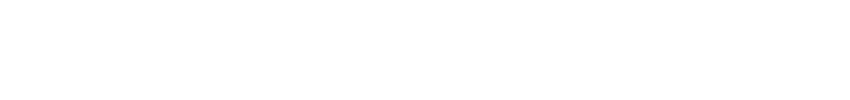

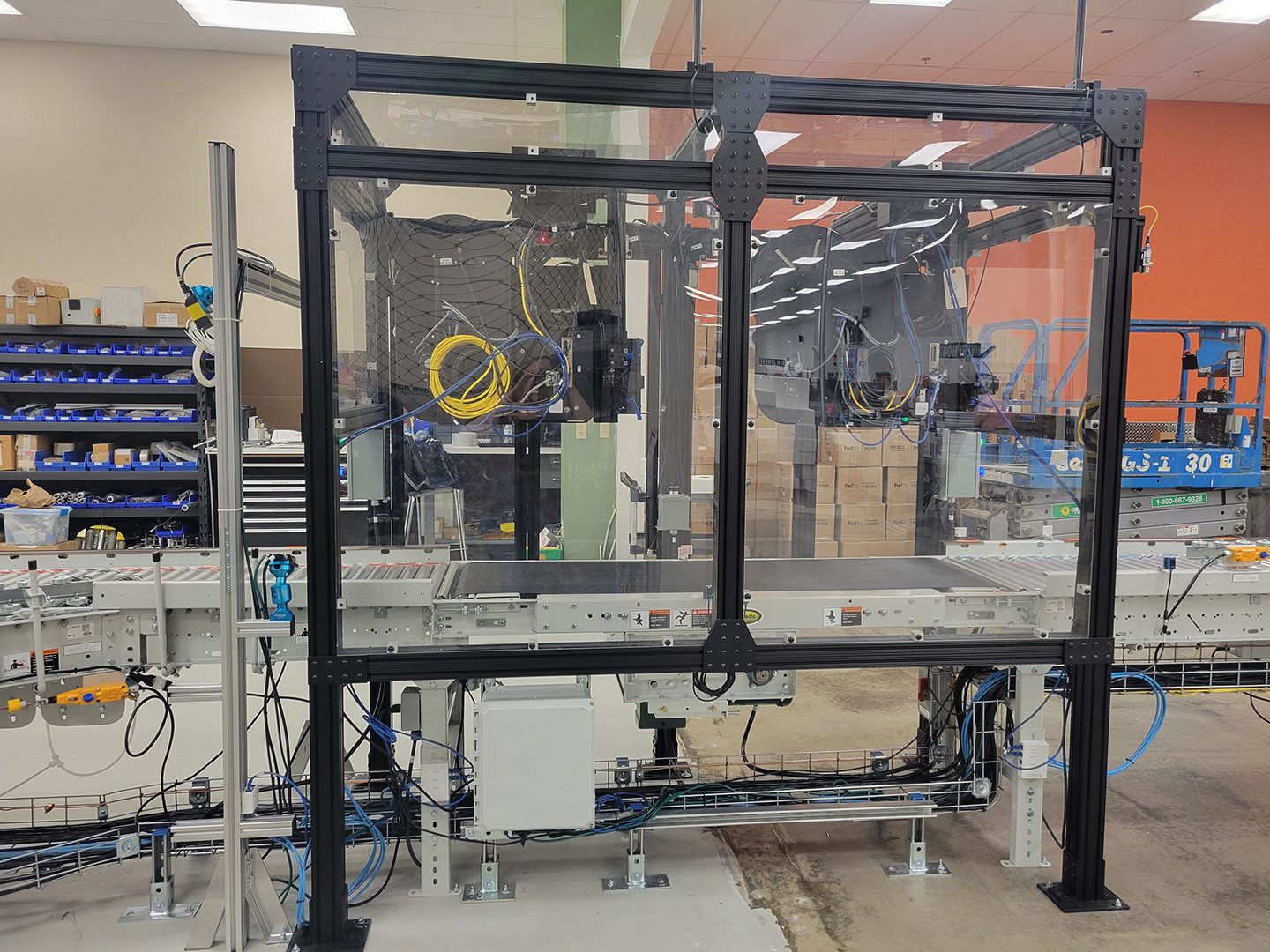

H & S Industrial and RSR Electric teamed up to help an online pharmacy establish a new efficient workflow to meet the increasing demands of their business. Ordering medications to be shipped directly to the patient’s home has been a resource for many years, providing cost and time savings for the customer. The worldwide COVID pandemic has made this service even more valuable. In order to provide better, faster deliveries without sacrificing important quality control, our client was seeking new equipment to speed up the flow and processing speed for orders.

The project involved removal of an old section of conveyor line from the existing processing line and placement of a new conveyor section, featuring multiple paths to move the medications more quickly through the facility. Additionally, a new shrink wrap machine and scale section were inserted into the process, to streamline the orders for shipment. A camera verification section was also included to reinforce quality control and ensure that the end customer is receiving the correct medication in the correct amounts.

With H & S and RSR working together on this project, we were able to provide a one-stop shop for this client. Our team was involved in the initial budgeting phase to ensure the customer was getting the best value for the equipment that would meet their needs and expectations. Because our team shared manpower there was little downtime between tasks, as everyone helped out where they were needed, keeping the customer’s product lines moving and eliminating delays in their shipments.

Because the project was located a considerable distance from our location in Lancaster County, coordination and planning was required to keep this project on track. Additionally, to limit downtime for the client, a very tight schedule was established to complete the work, including a two-week timeframe to finish the main part of the conveyor. Further challenges encountered during this project involved placing the equipment in a very compact space.

To overcome the hurdles created by the tight space and fast-paced schedule, the team took delivery of the conveyor at the RSR warehouse facility before the project start. This provided the opportunity to inspect the equipment and correct damage that occurred during over the road transportation while verifying the equipment layout. The team then sorted and staged the conveyor, to deliver it to the jobsite in multiple loads, according to a logistical plan, thus eliminating jobsite clutter and allowing a smooth installation. The careful management, open communication, and dedicated teamwork from H & S and RSR delivered the finished project within the tight scheduled timeframe and saved critical time.

The key to success on this project is by far the exceptional teamwork approach between the H & S Industrial and RSR Electric staff. Because our project team worked together so seamlessly, we were able to face any challenge, overcome any obstacle, and deliver the finished product that the customer envisioned. For our team, the ultimate satisfaction is found knowing that we played an important role in helping get medicines out faster to the people who need them.

Our Work

Exhibition Design & Fabrication

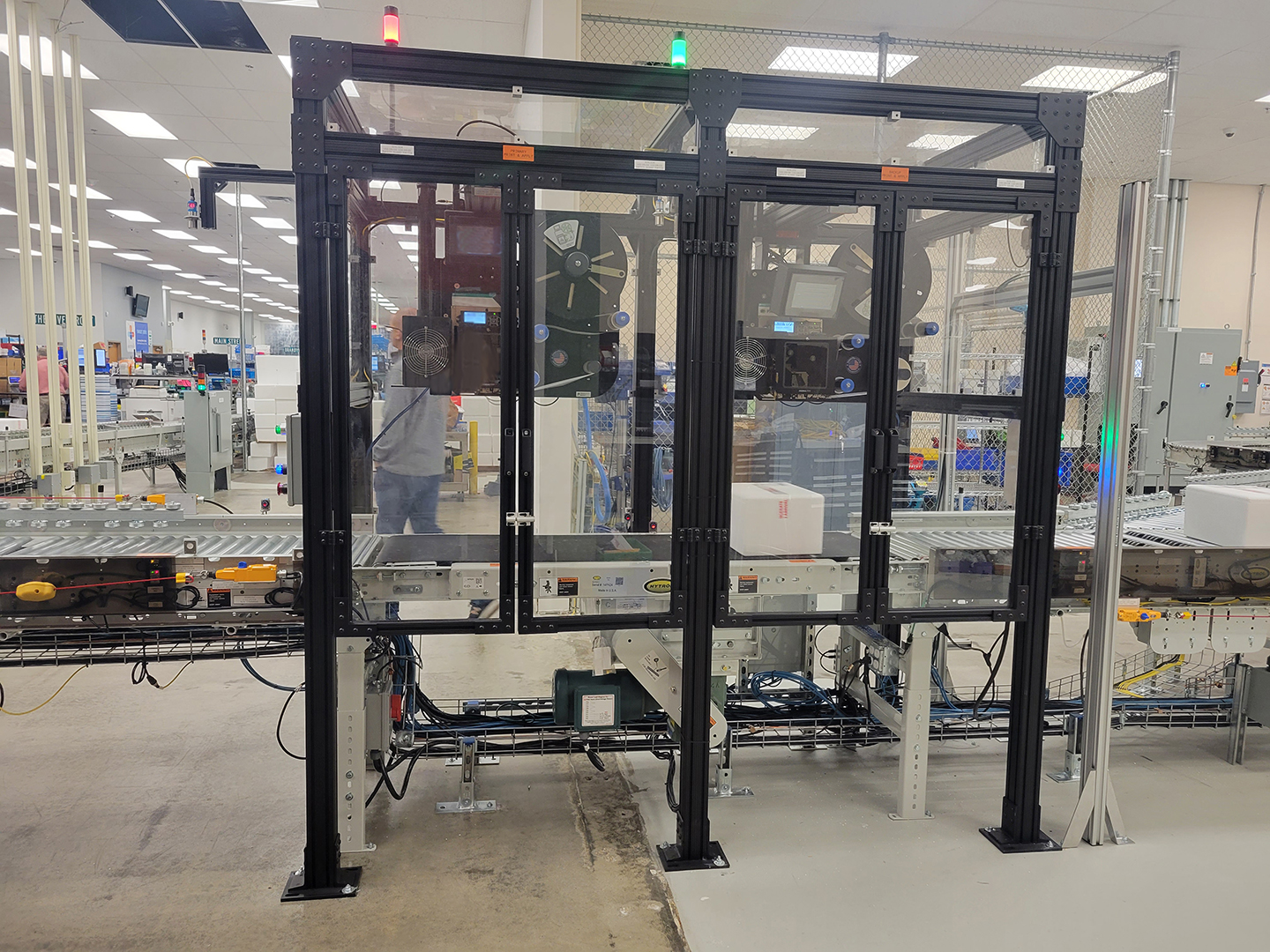

To go about finding the rising stars in the world of engineering, McCann NY, Lockheed Martin, Traction, Herr & Sacco and Nitro created the ultimate test: a challenge box. But not just any box. A 14-foot tall, mysterious inky-black monolith that can only be unlocked if you’re able to solve one of the world’s most impossible aerospace equations. In fact, the exact equation was a problem Lockheed Martin engineers had to solve for a real-world satellite mission. Lockheed Martin is bringing the box to some of the top engineering schools in America, starting with Virginia Tech. We’ll challenge students to ... [read more]

To go about finding the rising stars in the world of engineering, McCann NY, Lockheed Martin, Traction, Herr & Sacco and Nitro created the ultimate test: a challenge box. But not just any box. A 14-foot tall, mysterious inky-black monolith that can only be unlocked if you’re able to solve one of the world’s most impossible aerospace equations. In fact, the exact equation was a problem Lockheed Martin engineers had to solve for a real-world satellite mission. Lockheed Martin is bringing the box to some of the top engineering schools in America, starting with Virginia Tech. We’ll challenge students to see if they have the space skills it takes to unlock the box, and earn themselves the chance for a future at Lockheed Martin. But what exactly will they be unlocking? The universe. Inside, the winner will experience a 360-degree audio/visual journey though the stars, culminating with a grand prize and possibility of a job at Lockheed Martin where they can unlock the unknown on a daily basis.

Following Virginia Tech, the box will travel to a series of multi-day events taking place at the top engineering universities and networking/recruiting events across the country with new challenges and prizes. Let's start a new project together, request a quote here.

Our Work

Coffee Bean Silos & Sorting Infrastructure

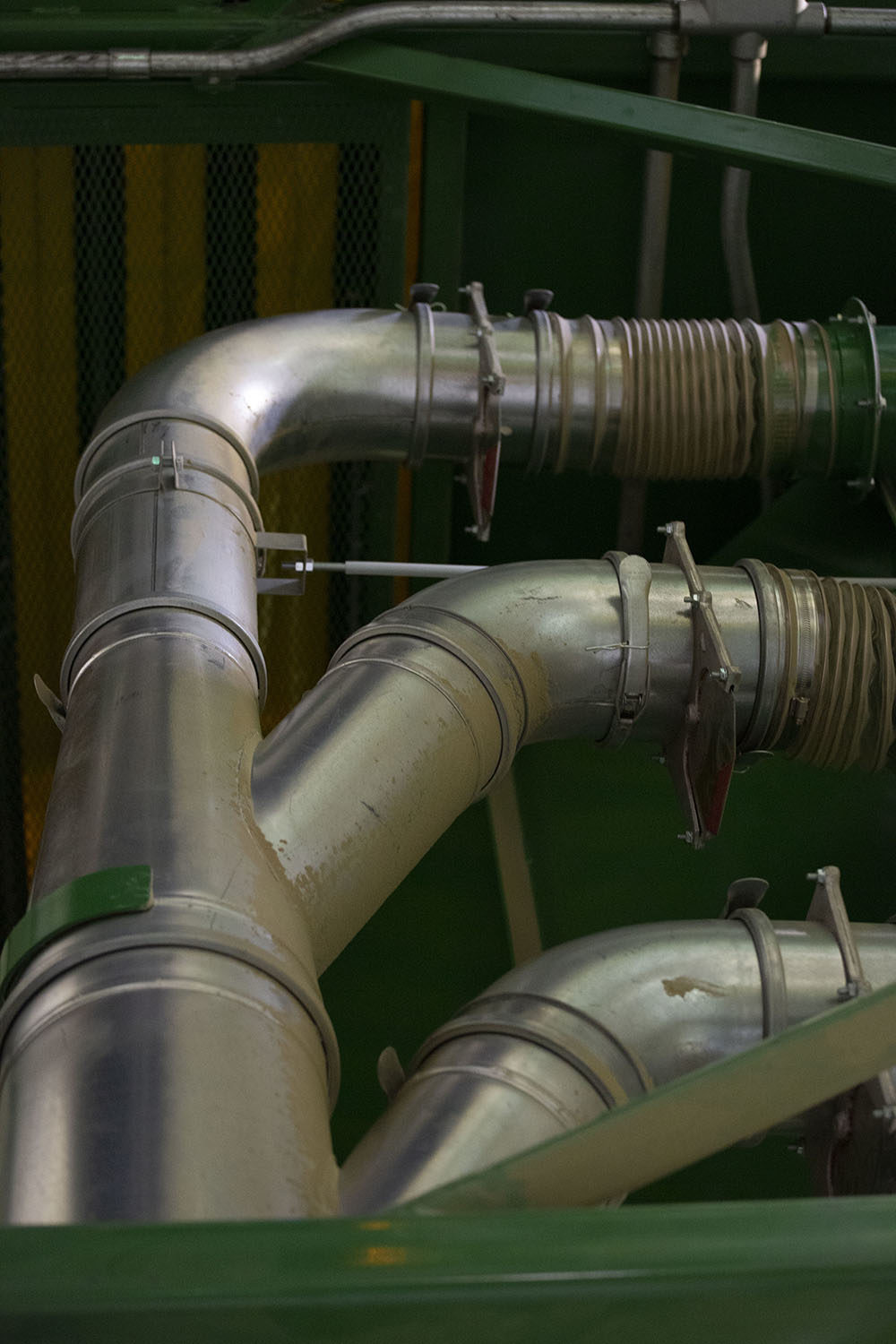

When it comes to large-scale, custom fabrication and installation for industrial manufacturing solutions, H&S excels. The project highlighted here was a product handling equipment installation that required fabrication, rigging, welding and piping for a global industry leader.

With a large amount of available floor space, H&S fabricated 42 large Bins (10 ft. x 11 ft. x 36 ft). These large bins were transported to the job site along with all of the procured equipment such as blowers, pumps and separators to be rigged into a new building while the structure was being built. The product handling equipment was connected with stainless ... [read more]

When it comes to large-scale, custom fabrication and installation for industrial manufacturing solutions, H&S excels. The project highlighted here was a product handling equipment installation that required fabrication, rigging, welding and piping for a global industry leader.

With a large amount of available floor space, H&S fabricated 42 large Bins (10 ft. x 11 ft. x 36 ft). These large bins were transported to the job site along with all of the procured equipment such as blowers, pumps and separators to be rigged into a new building while the structure was being built. The product handling equipment was connected with stainless steel piping throughout three different buildings, including crossing a pipe bridge over a roadway.

The bin fabrications were completed with a hi-def plasma cutting table, 20-ton bridge cranes and MIG welders. The materials were Hot Rolled Steel Plate with Tube Steel supports and Stiffeners weighing a total of 750,000 lbs. Each of the Bins were washed and coated on the interior, blasted and painted in our paint facility. The bins were delivered in five months with the entire facility-wide installation spanning six additional months. Let's start a new project together, request a quote here.

Our Work

Air Separation Column Box

The project highlighted here was a structural frame designed for use in the air separation industry that required both stainless steel and aluminum welding. With an ability to provide high purity welding within confined spaces, H&S fabricated the structural frame and enclosed it in steel plates, as well as filled it with heat exchangers, vessels, separators, and miles of aluminum pipe. The complex project was completed with the use of a plate shear, plate roll; vertical band saw, MIG welders, and 20-ton bridge cranes. The product was composed of a carbon steel and stainless steel structure with aluminum pipe. It ... [read more]

The project highlighted here was a structural frame designed for use in the air separation industry that required both stainless steel and aluminum welding. With an ability to provide high purity welding within confined spaces, H&S fabricated the structural frame and enclosed it in steel plates, as well as filled it with heat exchangers, vessels, separators, and miles of aluminum pipe. The complex project was completed with the use of a plate shear, plate roll; vertical band saw, MIG welders, and 20-ton bridge cranes. The product was composed of a carbon steel and stainless steel structure with aluminum pipe. It featured dimensions of 12.5" long, 14" wide, 100’ in height, and with a tightest tolerance of ±0.003". Weld integrity was confirmed with the use of dye penetrant, high pressure testing, and radiographs. The project represents a run of one piece delivered in ten months. Get started with us today and request a quote.

Our Work

Custom Flooring for the Chocolate Liquor Industry

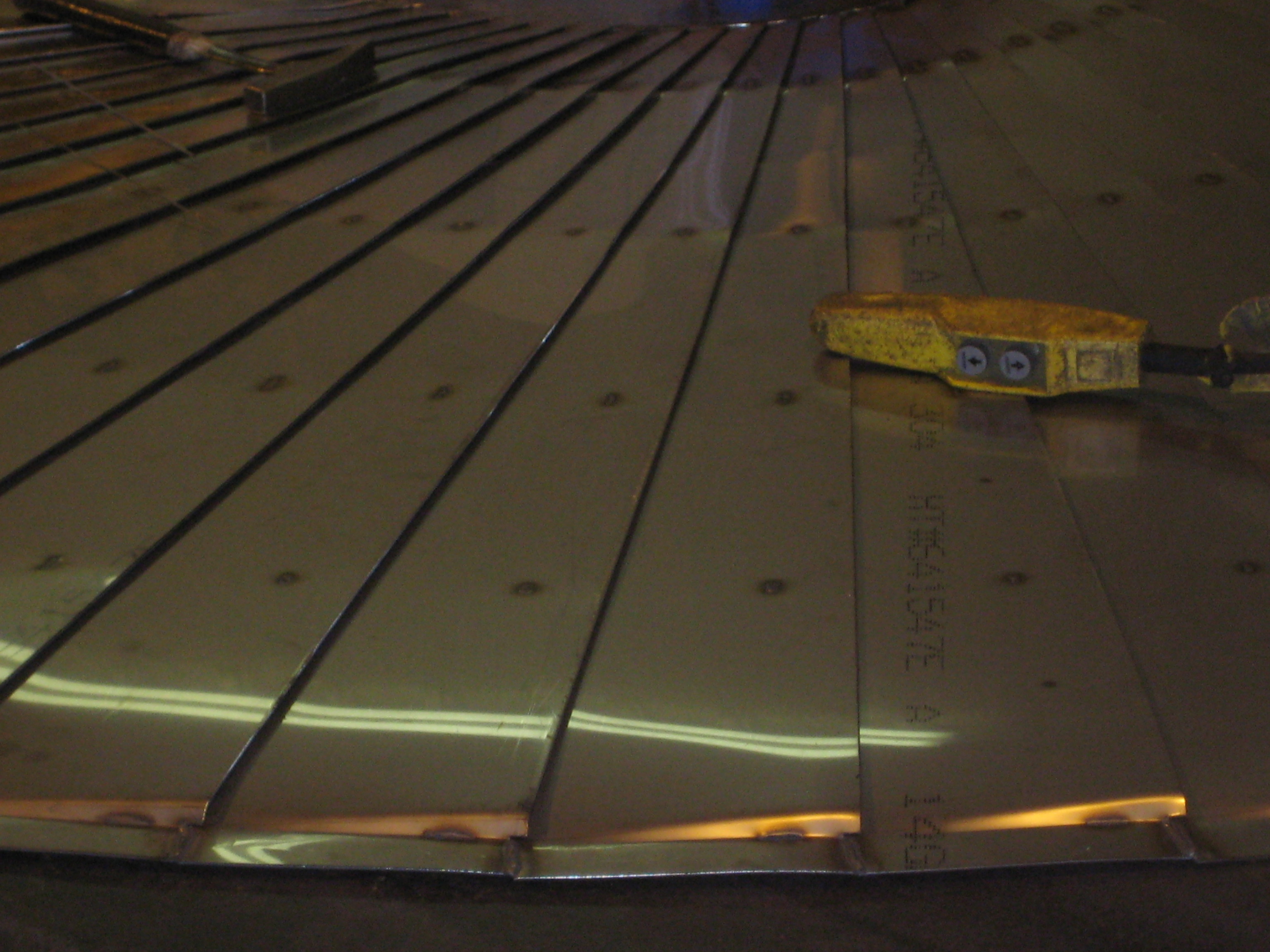

The project highlighted here was a stainless steel vented floor designed for use in the chocolate liquor industry. Millwright and sheet metal experts developed the tooling to create a profile of the fins, then formed them in-house and welded them together in a circular pattern, saving the customer a significant manufacturing cost. The floor was composed of 14 ga stainless steel and manufactured with the aid of a shear, band saw, and plasma machine. The part featured dimensions of 10.5’ by 14 ga, with a tightest tolerance of ±0.003". Integrity of the part was confirmed by the customer’s visual inspection... [read more]

The project highlighted here was a stainless steel vented floor designed for use in the chocolate liquor industry. Millwright and sheet metal experts developed the tooling to create a profile of the fins, then formed them in-house and welded them together in a circular pattern, saving the customer a significant manufacturing cost. The floor was composed of 14 ga stainless steel and manufactured with the aid of a shear, band saw, and plasma machine. The part featured dimensions of 10.5’ by 14 ga, with a tightest tolerance of ±0.003". Integrity of the part was confirmed by the customer’s visual inspection. It represents a run of one piece delivered and installed at the customer’s facility the next day. Get started with us today and request a quote.

Our Work

Teamwork Creates Streamlined Efficiency for Distribution of Medication

H & S Industrial and RSR Electric teamed up to help an online pharmacy establish a new efficient workflow to meet the increasing demands of their business. Ordering medications to be shipped directly to the patient’s home has been a resource for many years, providing cost and time savings for the customer. The worldwide COVID pandemic has made this service even more valuable. In order to provide better, faster deliveries without sacrificing important quality control, our client was seeking new equipment to speed up the flow and processing speed for orders.

The project involved removal of an old section of conveyor line from the existing processing line and placement of a new conveyor section, featuring multiple paths to move the medications more quickly through the facility. Additionally, a new shrink wrap machine and scale section were inserted into the process, to streamline the orders for shipment. A camera verification section was also included to reinforce quality control and ensure that the end customer is receiving the correct medication in the correct amounts.

With H & S and RSR working together on this project, we were able to provide a one-stop shop for this client. Our team was involved in the initial budgeting phase to ensure the customer was getting the best value for the equipment that would meet their needs and expectations. Because our team shared manpower there was little downtime between tasks, as everyone helped out where they were needed, keeping the customer’s product lines moving and eliminating delays in their shipments.

Because the project was located a considerable distance from our location in Lancaster County, coordination and planning was required to keep this project on track. Additionally, to limit downtime for the client, a very tight schedule was established to complete the work, including a two-week timeframe to finish the main part of the conveyor. Further challenges encountered during this project involved placing the equipment in a very compact space.

To overcome the hurdles created by the tight space and fast-paced schedule, the team took delivery of the conveyor at the RSR warehouse facility before the project start. This provided the opportunity to inspect the equipment and correct damage that occurred during over the road transportation while verifying the equipment layout. The team then sorted and staged the conveyor, to deliver it to the jobsite in multiple loads, according to a logistical plan, thus eliminating jobsite clutter and allowing a smooth installation. The careful management, open communication, and dedicated teamwork from H & S and RSR delivered the finished project within the tight scheduled timeframe and saved critical time.

The key to success on this project is by far the exceptional teamwork approach between the H & S Industrial and RSR Electric staff. Because our project team worked together so seamlessly, we were able to face any challenge, overcome any obstacle, and deliver the finished product that the customer envisioned. For our team, the ultimate satisfaction is found knowing that we played an important role in helping get medicines out faster to the people who need them.

Our Work

Exhibition Design & Fabrication

To go about finding the rising stars in the world of engineering, McCann NY, Lockheed Martin, Traction, Herr & Sacco and Nitro created the ultimate test: a challenge box. But not just any box. A 14-foot tall, mysterious inky-black monolith that can only be unlocked if you’re able to solve one of the world’s most impossible aerospace equations. In fact, the exact equation was a problem Lockheed Martin engineers had to solve for a real-world satellite mission. Lockheed Martin is bringing the box to some of the top engineering schools in America, starting with Virginia Tech. We’ll challenge students to see if they have the space skills it takes to unlock the box, and earn themselves the chance for a future at Lockheed Martin. But what exactly will they be unlocking? The universe. Inside, the winner will experience a 360-degree audio/visual journey though the stars, culminating with a grand prize and possibility of a job at Lockheed Martin where they can unlock the unknown on a daily basis.

Following Virginia Tech, the box will travel to a series of multi-day events taking place at the top engineering universities and networking/recruiting events across the country with new challenges and prizes. Let's start a new project together, request a quote here.

Our Work

Coffee Bean Silos & Sorting Infrastructure

When it comes to large-scale, custom fabrication and installation for industrial manufacturing solutions, H&S excels. The project highlighted here was a product handling equipment installation that required fabrication, rigging, welding and piping for a global industry leader.

With a large amount of available floor space, H&S fabricated 42 large Bins (10 ft. x 11 ft. x 36 ft). These large bins were transported to the job site along with all of the procured equipment such as blowers, pumps and separators to be rigged into a new building while the structure was being built. The product handling equipment was connected with stainless steel piping throughout three different buildings, including crossing a pipe bridge over a roadway.

The bin fabrications were completed with a hi-def plasma cutting table, 20-ton bridge cranes and MIG welders. The materials were Hot Rolled Steel Plate with Tube Steel supports and Stiffeners weighing a total of 750,000 lbs. Each of the Bins were washed and coated on the interior, blasted and painted in our paint facility. The bins were delivered in five months with the entire facility-wide installation spanning six additional months. Let's start a new project together, request a quote here.

Our Work

Air Separation Column Box

The project highlighted here was a structural frame designed for use in the air separation industry that required both stainless steel and aluminum welding. With an ability to provide high purity welding within confined spaces, H&S fabricated the structural frame and enclosed it in steel plates, as well as filled it with heat exchangers, vessels, separators, and miles of aluminum pipe. The complex project was completed with the use of a plate shear, plate roll; vertical band saw, MIG welders, and 20-ton bridge cranes. The product was composed of a carbon steel and stainless steel structure with aluminum pipe. It featured dimensions of 12.5" long, 14" wide, 100’ in height, and with a tightest tolerance of ±0.003". Weld integrity was confirmed with the use of dye penetrant, high pressure testing, and radiographs. The project represents a run of one piece delivered in ten months. Get started with us today and request a quote.

Our Work

Custom Flooring for the Chocolate Liquor Industry

The project highlighted here was a stainless steel vented floor designed for use in the chocolate liquor industry. Millwright and sheet metal experts developed the tooling to create a profile of the fins, then formed them in-house and welded them together in a circular pattern, saving the customer a significant manufacturing cost. The floor was composed of 14 ga stainless steel and manufactured with the aid of a shear, band saw, and plasma machine. The part featured dimensions of 10.5’ by 14 ga, with a tightest tolerance of ±0.003". Integrity of the part was confirmed by the customer’s visual inspection. It represents a run of one piece delivered and installed at the customer’s facility the next day. Get started with us today and request a quote.